Introduction

National and state-level authorities and the business community face increasing pressure to manage their waste better, resulting from the growing public demand to minimize the adverse impact of waste handling and disposal on public health and the environment. In summary, the broader objective of waste management is to reduce the waste we globally create and beneficially reuse the waste we generate.

This improvement initiative requires a structured and progressive move down the waste hierarchy pyramid (see figure 1) to steer away from the simple “dispose-and-forget” landfill approach. The desired direction in waste management comprises a complex mix of activities, such as reducing, reusing, recycling, composting, and anaerobic digestion, and thermal incinerating of the remaining waste as part of the Waste-to-Energy (WtE) process.

Fig. 1: Waste hierarchy pyramid

The latter is a waste treatment that results in the energy recovery generated as electricity or heat as a waste incineration product.

Europe was the first developer of the WtE process, with the earliest application dating back to 1874 in Nottingham, England. In the early and mid-twentieth century, industrialized nations, including Japan, parts of Europe, and the United States, started to use the thermal WtE.

This paper reviews the opportunities and challenges the specific area of WtE offers in today’s global economy. The global WtE market was valued at 35 billion USD in 2019 and is expected to increase at a CAGR of 5% through the 2020s.[1]

WtE as part of the waste management system

Historically, municipal solid waste was simply dumped in disused quarries or on land allocated for waste disposal in a process known as landfill. A landfill is the most convenient “dispose-and-forget” approach and has the lowest immediate cost.

However, there are several problems with a landfill solution, the most significant of which are the presence of leachate and the creation of greenhouse gases. Leachate is a soup of organic matter, including aldehydes, inorganic matter (ammonia, heavy metals, and other toxins such as PCBs & dioxins). This leachate, if not managed, can contaminate groundwater, rivers, and drinking water. Additionally, landfills are estimated to account for approximately 5% of global greenhouse gas emissions.[1]

Several waste management strategies have been developed to overcome landfill problems. These include:

- Lining landfill sites with geo-membranes to prevent leachate contamination.

- Reduction, reuse, and recycling of packaging to decrease the total quantity of waste.

- Separate disposal and processing of electronic wastes to prevent heavy metal leachate and to recover valuable materials.

- Composting of organic waste to reduce greenhouse gas emissions.

- Recovery and use of WtE applications to further reduce waste volumes and supply energy in the form of heat or electricity.

WtE applications are one part of a complex waste management landscape. In general, it should be applied only if the waste cannot be reasonably avoided, reused, or recycled, as these options typically have a lower total public health and environmental footprint.

Waste to Energy Technologies

The most common WtE technologies are incineration and anaerobic digestion.

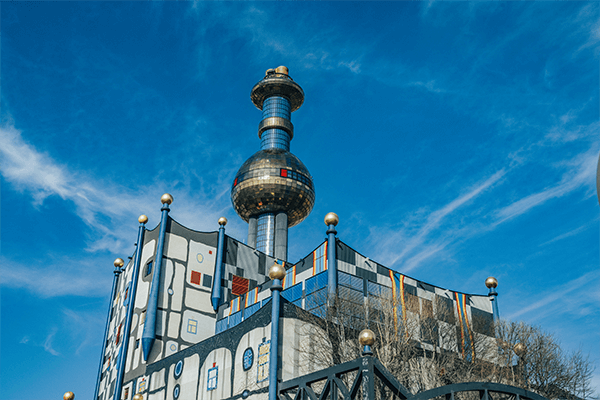

Incineration is the combustion of waste. This releases heat which can be recovered for power generation, hot water or steam production, and potentially cold-water production by adsorption chilling. Incineration reduces the volume of waste by around 95% and reduces the release of greenhouse gases arising from organic waste simply dropped into landfills.

Fig. 2: Spittelau waste incineration plant in Vienna, Austria

Anaerobic digestion is the breakdown of biodegradable waste by living microorganisms in the absence of oxygen. It produces biogas containing methane and carbon dioxide, which can be burned to generate heat and power. A by-product, called digestate, can be used as feedstock for ethanol production and additionally as fertilizer.

Considerations for the application of WtE

WtE technologies have some significant caveats which need to be addressed to deliver effective applications.

In all cases, the waste needs to be suitably separated and classified upstream. Anaerobic digestion can only take biodegradable waste as a feedstock, such as household or commercial food waste. On the other hand, incineration should not be fed with wet biomass like household food waste, as the energy content is not high enough to burn efficiently.

Incineration requires a fuel with a minimum average calorific value of 7 MJ/kg for combustion without auxiliary fuel. Metals and glass have no calorific value, so they should also be separated out of the stream to be incinerated. Failure to effectively separate waste is the most significant root cause of WtE project failure.

Incineration is most suited to processing plastics, textiles, and paper. However, each of these has its separate recycling route. Incineration capacity should only be built to the extent to handle waste streams uneconomic or not possible to recycle.

Incineration of waste containing chlorine, such as PVC plastics, can lead to the plant’s heat exchange surfaces’ rapid corrosion. These need to be removed from the feedstock.

Incomplete combustion can release toxins called dioxins and furans. Appropriate combustion control is essential for the environmentally compliant production of energy from waste. The combustion temperature needs to be at least 850°C with a minimum retention time of 2 seconds.[1] Flue gas oxygen concentration should be at least 6% in volume, and the exhaust gas must be cooled quickly.[2]

Likewise, if they are present in the waste, heavy metals would be emitted if not controlled. Emissions control is of particular importance, as the most economical locations for WtE plants are near to centers of population and industry.

All new WtE plants in OECD countries incinerating waste must meet strict emission standards, including those regarding nitrogen oxides (NOx), sulfur dioxide (SO2), heavy metals, and dioxins.[3]

WtE prospects – Global growth trend?

The forerunners

WtE is well-advanced in some regions and countries, such as Northern Europe, Japan & Singapore. For example, Sweden incinerates approximately half its municipal waste to generate heat and power across its 34 WtE assets. It sends only 1% of its municipal waste to landfills.

However, the continual room for growth in these regions is limited, mainly as there is concern that over build-out of waste to energy facilities is detrimental to the recycling rate. Further, there is likely to be a reduction in the quantity of waste due to the push to phase out single-use items, which will bring down per capita waste volumes.

The current wave

China is at the forefront of the current wave of WtE build-out. China has more than 7GW of WtE production capacity, with circa 350 plants in operation in 2017[1], easily the largest WtE generator globally. China has developed robust technologies using fluidized bed combustion for relatively low calorific value waste streams. China’s growing affluence brings with it increasing consumption, with the per capita waste expected to increase by 40% by 2050.[2]

Much of Southeast Asia, currently taking over China’s mantle as the world’s workshop, does already or is soon likely to have the right conditions conducive to the rollout of WtE. Thailand already has tax incentives and subsidies in place to promote a WtE rollout. The current installed capacity is in the range of 200MW, and licenses have been granted for a further 500MW. A lack of waste sorting is, however, hampering progress. Similarly, Indonesia, Vietnam, and Malaysia are all supporting the build-out of WtE infrastructure.

India has built more than 90 WtE plants with a total capacity of over 250MW[3] . It has a target to generate 800 MW, supported by a WtE electricity price almost double the regular market price. Unfortunately, many of these projects are operating ineffectively, and some have already shut down. This is again due to the waste streams process providing unsuitable fuel mix for efficient combustion. Most cities in India still collect unsegregated waste, and WtE operators are incentivized to accept unsegregated waste as the chargeable fees are higher. [4]

Future growth

In Latin America and Africa, over 90% of municipal waste currently goes to landfills or open dumps. While much of Africa and Latin America do not yet meet the conditions conducive to the rollout of WtE, some initial steps are evident. Mexico City has no natural drainage and is surrounded by mountains and volcanoes, making waste management challenging. The first WtE incineration plant to serve Mexico City is in the planning phase.[5]

Africa is expected to outperform other regions in terms of growth in the first half of the decade and continue to be home to seven of the world’s ten fastest-growing economies.[6] Over the longer-term in Africa, the urban population is expected to roughly double by 2050 [7] The first green shoots of a market for WtE in Africa are already emerging.

Ethiopia hosts Africa’s first WtE plant, Reppie[8] , which will incinerate 1,400 tonnes of waste/day in Addis Ababa, generating up to 110 MWt. Cape Town in South Africa will host Africa’s second, which will employ waste separation and an anaerobic digester and supply bio-CNG rather than electricity.

Conclusion

In conclusion, the early adopter nations may be nearing or, in some cases, have even overshot the optimum deployment of WtE as part of an integrated waste management strategy. Globally there is vast potential to develop WtE as part of more integrated, environmentally sound waste management and energy production strategies. The lessons from poor waste separation need to be learned to deliver the required successful outcomes.

WtE facilities require significant capital investment. It can be expected that any financing of such projects would require the same high environmental standards required

Authors: Martin Lord and Trevor Bailey

[1] Statista: https://www.statista.com/statistics/480452/market-value-of-waste-to-energy-globally-projection/

[2] Stocker, T. IPCC, 2013: Technical Summary. In Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2013; pp. 159–254.

[3] European Commission (2018).

[4] European Commission (2018).” Best Available Techniques(BAT) Reference Document for Waste Incineration”

[5] 2000/76/EC EU incineration of waste directive

[6] https://www.eco-business.com/news/waste-to-energy-a-renewable-opportunity-for-southeast-asia/

[7] https://www.mordorintelligence.com/industry-reports/china-waste-to-energy-market-industry

[8] https://energy.economictimes.indiatimes.com/news/power/waste-to-energy-why-a-rs-10000-crore-industry-is-facing-issues/69685189

[9] https://www.downtoearth.org.in/news/waste/trash-fired-power-plants-wasted-in-india-63984

[10] https://global-recycling.info/archives/1659

[11] https://www.brookings.edu/multi-chapter-report/foresight-africa-top-priorities-for-the-continent-in-2020/

[12] https://assets.publishing.service.gov.uk/media/57a08a08e5274a27b20003b5/130530_ENV_CitAdaMit_BRIEF2.pdf

[13] https://static1.squarespace.com/static/57c7f80620099eafefefe77a/t/5b31caeff950b7cb65f7437d/1529989903242/Reppi+Brochure+%28technical+detail%29.pdf