Rising demand for electricity coming from new industrial development, vehicle and building electrification, and increasing power consumption from computing are pushing utilities and businesses to find stable sources of power wherever they can. The development of these new centers of power consumption is driving businesses and utilities to look for sources of generation wherever they can. Coupled with pressures to reduce emissions from power, their attention is increasingly focused on low emission hydrogen as a fuel source.

But there are many routes to hydrogen production, and some are more carbon intensive than others.

Industry has created a shorthand for the different types of pathways to hydrogen generation using a color wheel that’s growing increasingly vibrant as new resources emerge.

From white hydrogen which could be produced using techniques borrowed from the oil and gas industry to blue hydrogen combining traditional fossil fuel methods with carbon capture and storage, industrial players need to understand the ways to produce this vital low emission source for power.

The Hydrogen Color Wheel

White Hydrogen

White Hydrogen

White hydrogen is produced from natural geological sources where hydrogen is found in underground deposits, essentially as a result of natural processes. The extraction of white hydrogen involves tapping into these reserves and capturing the hydrogen for use. This method is relatively rare and still under exploration for its potential and scalability. The environmental impact and sustainability of white hydrogen production depend on the specific extraction methods and the lifecycle analysis of the process. Since it does not directly involve the use of fossil fuels or electrolysis powered by electricity, it’s considered a low-emission source, provided that the extraction process is environmentally friendly.

Green Hydrogen

Green hydrogen is produced through the electrolysis of water, using electricity generated from renewable energy sources such as wind, solar, or hydroelectric power. This method is considered the most environmentally friendly, as it emits no greenhouse gases during the production process. Green hydrogen is pivotal for achieving 100% renewable energy adoption, as it provides a sustainable and zero-emission energy carrier that can be used across various sectors, including transportation, industry, and power generation.

Blue Hydrogen

Blue hydrogen is produced from natural gas through steam methane reforming (SMR) or autothermal reforming (ATR), combined with carbon capture and storage (CCS) technologies. While this process still involves fossil fuels, the carbon emissions are captured and stored underground or utilized in other applications, significantly reducing the environmental impact compared to traditional hydrogen production methods. Blue hydrogen serves as a transitional solution, offering a lower-carbon alternative until green hydrogen production can be scaled up and made more economically viable.

Grey Hydrogen

Grey hydrogen is currently the most common form of hydrogen production. It is produced from natural gas through SMR without capturing the CO2 emissions. This method is energy-intensive and releases significant amounts of carbon dioxide into the atmosphere, contributing to climate change. The shift from grey to green or blue hydrogen is essential for reducing the carbon footprint of hydrogen production.

Turquoise Hydrogen

Turquoise hydrogen is produced through a process called methane pyrolysis, which decomposes methane into hydrogen and solid carbon. This method potentially offers a low-emission alternative to traditional hydrogen production, as the solid carbon can be used as a commodity in various industries, provided it is not released into the atmosphere. However, methane pyrolysis is still in the early stages of development and not yet widely adopted.

Gold Hydrogen

Extracted from depleted oil wells, gold hydrogen is made from residual oil hydrocarbons that cannot be profitably extracted in their current form. By injecting proprietary mixes of bacteria and chemicals into the depleted wells, companies hope to break the oil residue down into hydrogen and CO2. The process can reinvigorate old wells, but companies need to address the potential carbon dioxide emissions from the wells.

Pink (or Purple) Hydrogen

Pink hydrogen, also known as purple hydrogen, is produced through electrolysis powered by nuclear energy. This method is considered low-carbon, as nuclear power plants emit minimal greenhouse gases during operation. However, the environmental and safety concerns associated with nuclear energy, such as radioactive waste, make pink hydrogen a controversial option.

Brown and Black Hydrogen

Brown and black hydrogen are produced from coal through gasification. These methods are the least environmentally friendly, emitting large amounts of CO2 and other pollutants. They are primarily used in regions with abundant coal reserves but are increasingly being phased out in favor of cleaner alternatives.

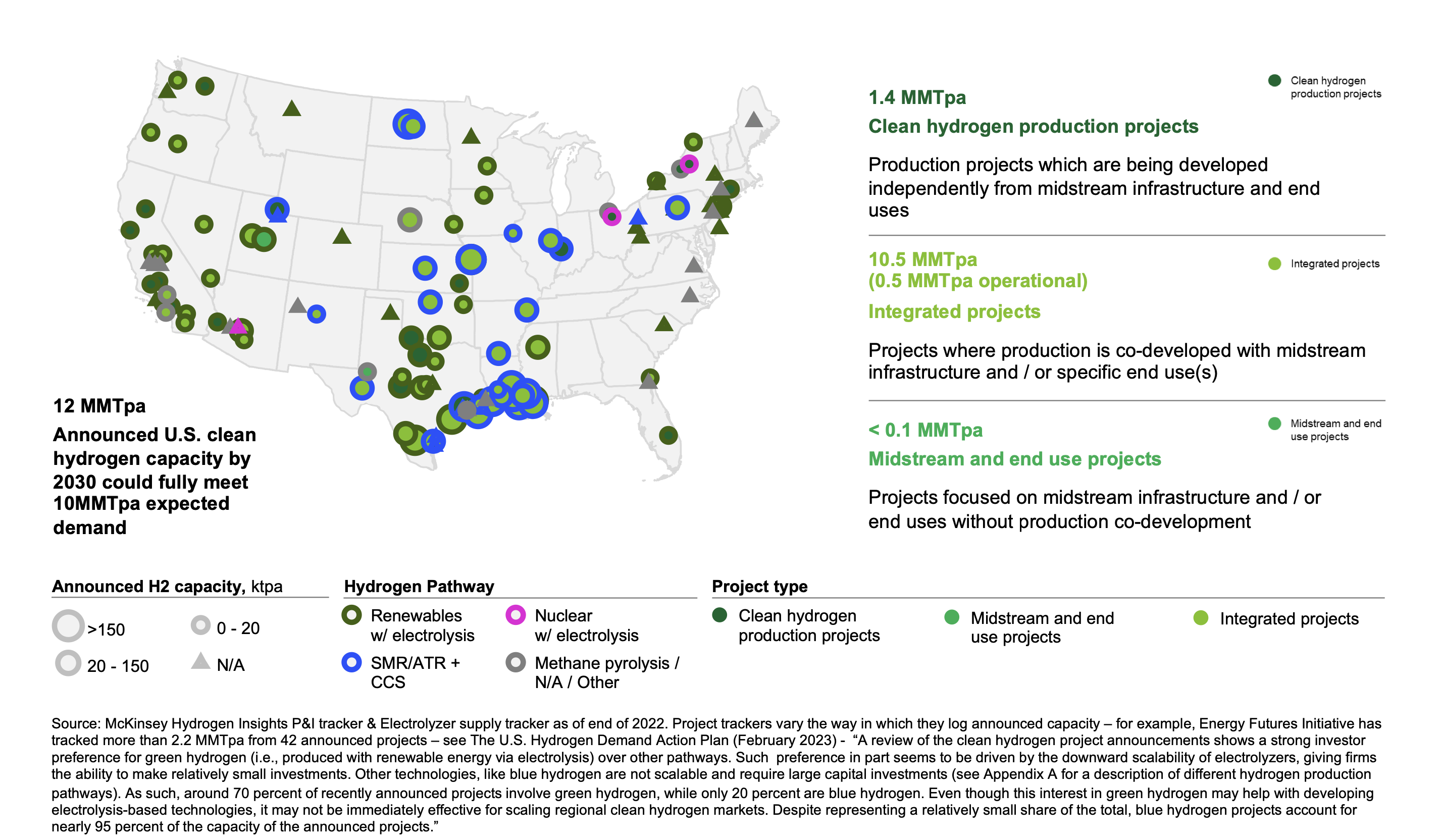

Projects From Around the Wheel

Image Credit: US Department of Energy, “Pathways to Commercial Liftoff: Clean Hydrogen”

Green Hydrogen Projects

Advanced Clean Energy Storage (ACES) Project, Utah – One of the world’s largest green hydrogen storage initiatives, the ACES project aims to convert renewable energy into hydrogen and store it in underground salt caverns. This project, a collaboration between Mitsubishi Hitachi Power Systems and Magnum Development, is a significant step towards utilizing green hydrogen for energy storage and grid balancing.

Pink Hydrogen Projects

Natrium Reactor Demonstration Project by TerraPower and PacifiCorp – This project in Wyoming, USA, plans to use nuclear energy to produce hydrogen. The Natrium reactor is designed to be more flexible and cost-effective, potentially providing a low-carbon source for hydrogen production.

Blue Hydrogen Projects

Project Longship, Texas – A notable blue hydrogen project, led by major energy companies, focuses on producing hydrogen from natural gas with carbon capture and storage (CCS). This project aims to significantly reduce carbon emissions associated with hydrogen production, aligning with broader efforts to decarbonize the energy sector.

Turquoise Hydrogen Projects

Monolith Materials in Nebraska, USA – Monolith Materials uses methane pyrolysis to produce hydrogen and solid carbon black, a material used in various industries. This process significantly reduces CO2 emissions compared to traditional hydrogen production methods

Gold Hydrogen Projects

Gold H2, Texas -Gold H2 is a subsidiary of the Houston-based startup Cemvita Factory, which has raised and close funding from the gas transportation services firm, Chart Industries, and an early stage venture firm. Using a mix of bacteria and chemicals, the company has piloted production of an undisclosed amount of hydrogen at well sites in Texas.